7232 Bell School Line,

Milton ON L9E 0N7, Canada.

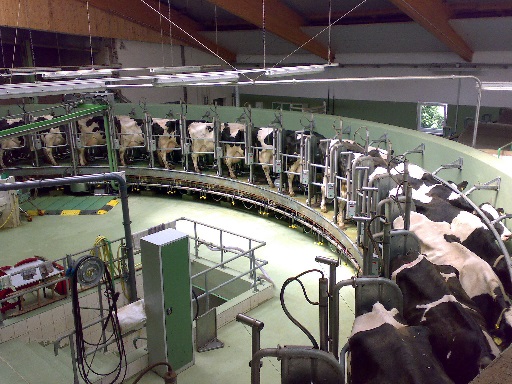

Milking on the increase

The capacity of the milking robot gives you the option of either milking 90 medium level producing cows or 65 high producing cows per robot. At Gimbo Dairy Farm they are aiming for the high production option, currently milking 400 cows in 7 VMS. The eighth VMS will be installed soon. The production is 28 litres/cow /day and average number of milkings per day is 2.4. Juan is not satisfied with this level of production. He has been working with a cross-breed of Holsteins and Swedish Red, and the strategy has not met his expectations, so he is now in the process of switching back to pure Holsteins to increase production.